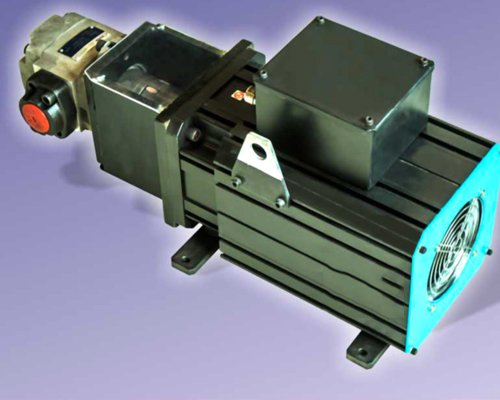

Servo System For Injection

A servo system for an injection molding machine uses servo motors and drives to precisely control the injection, clamping, and ejection motions, replacing traditional hydraulic systems for higher accuracy and efficiency. It enables precise control of screw position, injection speed, clamp movement, and ejection timing, ensuring consistent part quality. The system is highly energy-efficient, drawing power only when motion is required, which reduces electricity consumption and operational costs. Rapid acceleration and deceleration of servo motors shorten cycle times while maintaining accuracy, and quieter operation reduces noise and heat generation on the shop floor.

Key Features

Servo systems in injection moulding machines deliver high precision, fast response, and stable control for injection and clamping operations.

- Ensures accurate injection, clamp, and ejector movements.

- Reduces power consumption and operational costs.

- Speeds up production with rapid servo response.

- Quieter operation with minimal heat generation.

Servo System For Injection – Specifications

| Controller Type | PLC-based Injection Molding Controller |

| HMI Display | 7″ / 10″ Color Touch Screen |

| CPU Scan Time | ≤ 1 ms |

| Digital I/O | 32–128 Points |

| Analog I/O | 8–32 Inputs, 4–16 Outputs |

| Temperature Control | 4–16 Zones, PID Control, 0–400°C |

| Motion Control | Servo motor compatible (Injection, Clamp, Ejector) |

| Communication | Ethernet, RS-485, Modbus RTU/TCP |

| Safety Features | E-Stop, Door Interlock, Alarms & Diagnostics |

| Power Supply | PLC: 110–240V AC, Control: 24V DC |