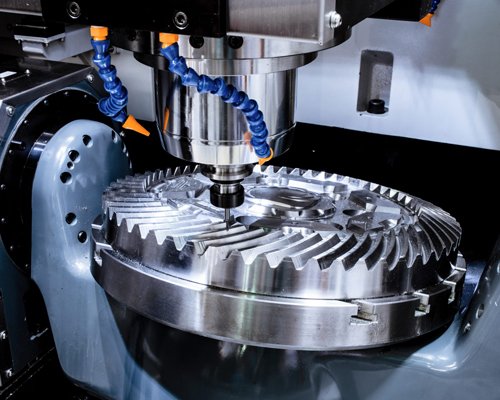

CNC Machine

Our CNC machine is equipped with advanced technology that ensures high-precision operations for plastic components. It allows accurate cutting, shaping, and finishing, delivering uniform quality and repeatable results every time. The computer-controlled process supports complex designs with minimal manual intervention, reducing errors and material wastage. Regular maintenance and skilled operation ensure smooth performance and a long service life. By integrating CNC machinery into our workflow, we improve production efficiency, maintain consistency, and enhance the overall quality of our plastic products.

Key Features

Our CNC machines deliver high precision and consistent performance for complex plastic components. They ensure efficiency, reliability, and durability with minimal maintenance and flawless output.

- High precision and accuracy for consistent cutting and finishing

- Capable of handling intricate and custom plastic components

- Efficient operation with reduced production time and minimal errors

- Durable construction requiring low maintenance and long service life

CNC Machine– Specifications

| Machine Type | CNC Milling / CNC Turning Machine |

| Power Supply | 3 Phase, 415V AC |

| Spindle Speed | 50–5000 RPM (depending on model) |

| X, Y, Z Travel | 300mm × 200mm × 200mm (example – model dependent) |

| Tooling System | Multi-tool automatic changer |

| Material Compatibility | PP, HDPE, LDPE, ABS, PVC, Polycarbonate |

| Accuracy | ±0.01 mm |

| Repeatability | ±0.005 mm |

| Cooling System | Liquid or air cooling for smooth operation |

| Operation Mode | Semi-automatic / Fully automatic |

| Software Support | Compatible with CAD/CAM software |